It will fit the following vehicle year, make and model:

Fits:

Replacement Parts for Jeep Wrangler Base Sport 2018-2023 ROP Brake Code BRY, With Standard 328MM= 12 29/32 Inch Rear Rotors & 330MM = 13 Inch Front Rotors

2018-2023 Replacement Parts for Jeep Wrangler Base Sport S ROP Brake Code BRY, With Standard 328MM= 12 29/32 Inch Rear Rotors & 330MM = 13 Inch Front Rotors

2018 Replacement Parts for Wrangler JK, all

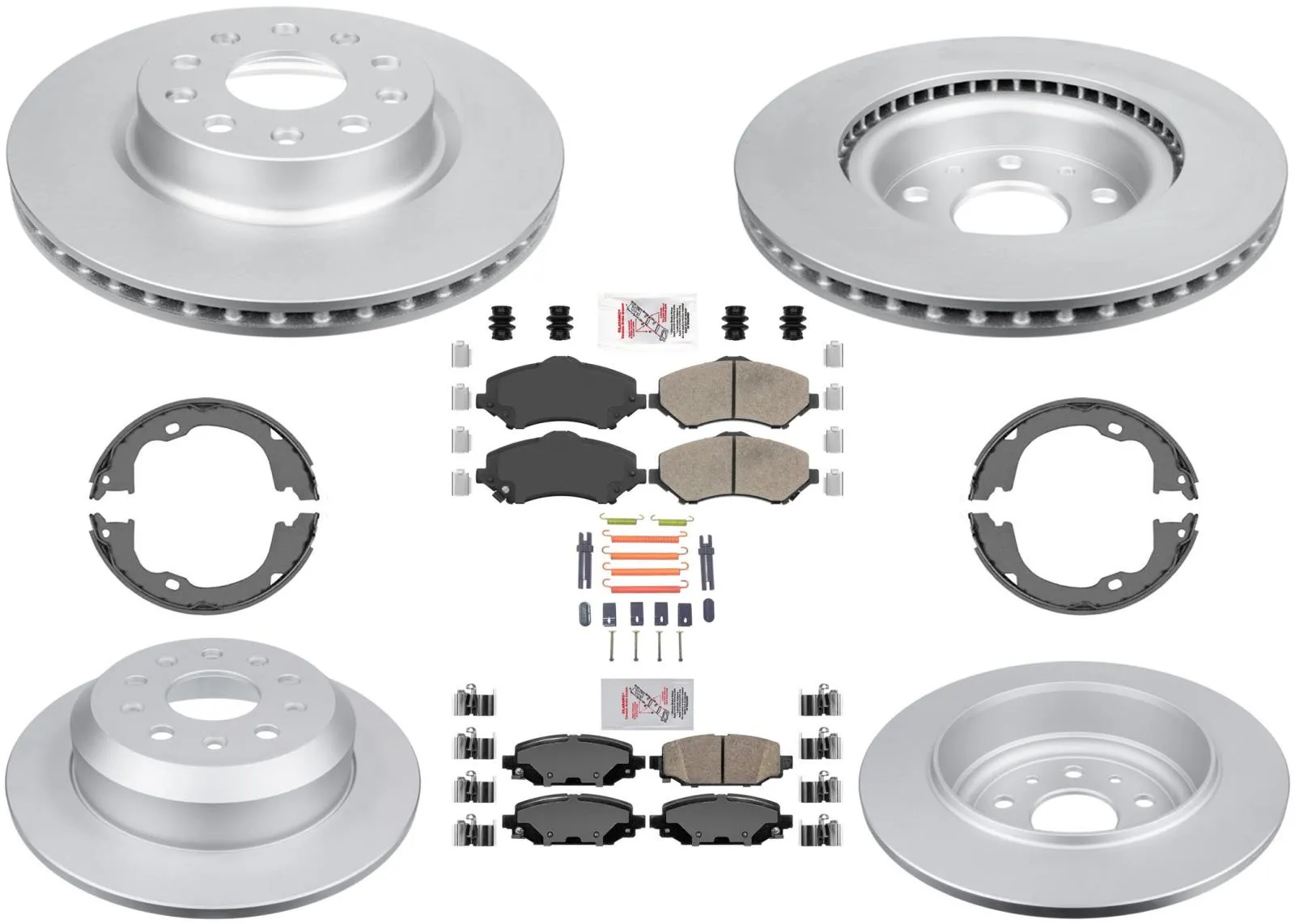

Kit Includes: 8pc (Fits Front & Rear)

2x Part# 591413 Ameri Pro Rust Prevented Powder Coated Disc Front Brake Rotors 330MM = 13 Inch

1x Part# PTC1273 Ameri Pro Premium Front Ceramic pad set, with hardware

2x Part# 591416 Ameri Pro Rust Prevented Powder Coated Disc Rear Brake Rotors 328MM = 12 29/32 Inch

1x Part# PRC2172 Ameri Pro Premium Rear Ceramic pad set, with hardware

1x Part# 941 1404-232423 Rear Organic Parking-Emergency Brake Shoe Set, fits inside rear rotors

1x Part# 7419K 118.67004 Rear Parking-Emergency Brake Shoe Spring Kit

Premium AME Coated Brake Rotor Series

AME Coated Brake Disc Rotors meet and exceed the performance of the original equipment rotors. These rotors have more carbon content, painted hubs, and a new dry-oil protection coating. The new Rotor now services the vehicle even better, with optimal thermal conductivity, and a higher resistance to distortion and thermal cracking. The improved dry-oil protection coating protects even longer against corrosion. Dipped and not sprayed, the dry-oil finish protects on both vented and non-vented rotors. This dry film does not need to be cleaned off the rotor at installation – it is “ready to go” out of the box.

AME Coated Rotors are engineered to withstand the service duty requirements of high energy stopping that emergency vehicles demand. They provide best-in-class performance coupled with quiet operation and long life. Used with AME disc pads, this combination will exceed the expectations and demands of all customer unique vehicle service requirements without sacrificing every day braking comfort.

Quality & Safety

Our precise research and development process assures you are buying a rotor that meets or exceeds the original in performance. All our products are objectively tested by accredited independent laboratories:

Link Engineering Labs – Conformity Assessment Certification and Greening Labs.

- SAE J2928 – Tests for stability during high heat braking conditions

- SAE J2933 – Modal test to assure quiet operation

- SAE J431 – Verifies material composition and properties (stability and strength)

Cart(

Cart(